01/2018 - 02/2019

Team

- Bram de Haas

Key learning points

- 3D printing

- Wireless communication

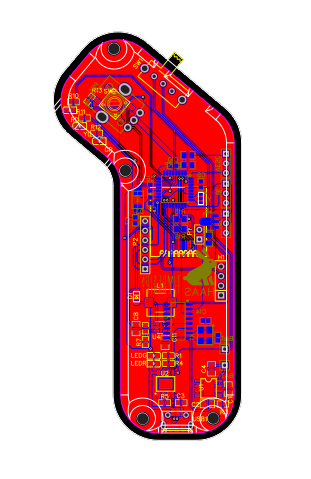

- PCB design

Electric longboard

Together with an electrical engineer, I have been working on an electric longboard. Apart from the personal need for a practical and convenient means of transport, we were interested in developing our prototyping and product development skills.

Reflection

Within our small team, my main responsibilities consisted of the 3D modeling and software. Whereas most of my prototypes should only be capable of withstanding a small demonstration or user test, durability demands were significantly higher for this project.

Several options for wireless transmission were explored and tested for the remote of the system. Flaws were detected in various options, such as delays, vulnerability to noise or limited range. Following these tests, a proper match was found, simultaneously improving my knowledge on the other options, and types of applications they could be used for.

Regarding the physical components of the longboard, I encountered various new techniques and tools as well. Initial 3D printed enclosures to protect the electronics underneath the longboard did not withstand the stress of daily use. Instead, the printed covers were used as a mold for fiberglass sheets in combination with polyester resin. Attaching the motor to the longboard was my first experience in welding.

In conclusion, this project has greatly increased my knowledge in prototyping, with a specific focus on creating products with sufficient durability for daily use. These skills match my interests regarding future work as a designer. Being able to create innovative and interesting products was my main reason for becoming an Industrial Design / Computer Vision Developer, and still drives me, up to today. I intend not to limit myself to ideation and research phases and wish to be closely involved in the final phases of projects, leading to the finished product.